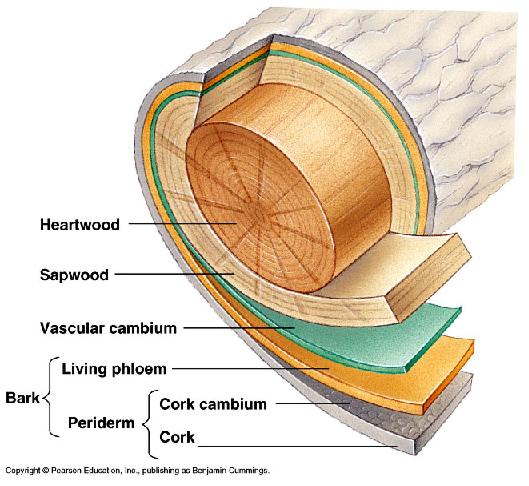

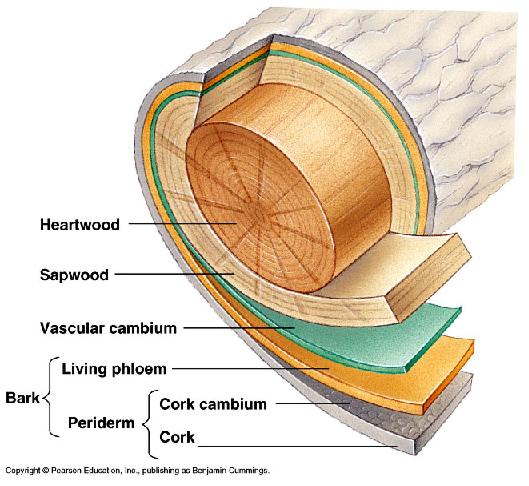

Just look at a Plants stalk. The

woof protects the inner wood from climate, insect and other danger. Just inside the woof there is a skinny layer called the

cambium, whose cells turn out to be both woof and internal wood. Next is

sapwood, which carry beneficial sap throughout the tree the same way our blood flows all the way through our bodies to nourish us.

Heartwood is the deepest part of the stalk, and even though it is not living, it provide the tree with potency and structure.

If you actually want to be familiar with paper and paper-making, you have got to get to know about plants.

Trees & Plants are all around you. But have you ever really

consideration about how they are put mutually? They are pretty cool.

All that lumber material is shaped of fibbers, small fiber strands stuck jointly with a ordinary adhesive material called lignin. It is by sorting out and reorganizes those fibbers that we make paper.

Consider the source

Several papers are made from brand-new trees – either tiny trees

harvest just for that principle, or from sawmill knock-knacks left over

when larger trees are made into lumber. A next source of paper-making

substance is used fiber. Every year, many more paper are recycled – its fibbers is used for second, third or fourth times.

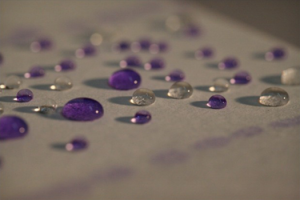

More or less all of the paper you use nowadays is finished of wood

fibbers. Some specialty papers, like stationery and currency, are made

from linen, cotton, or other plants. Other papers contain a mixture of

roughage fibers and synthetics such as latex. Still others are made

completely from synthetic materials such as poly-olefin. You might find

latex in a water-resistant mariner’s chart, or poly-olefin in a rugged

courier envelope. But you’ll find natural fiber paper almost everywhere!

Lumber is wood?

Lumber is wood?

All tree species grows a certain way, and that affects the way its wood

looks and performs. Foresters separate trees into two categories: hardwood and softwood species.

Hardwood trees: It’s

such as oaks and maples have wood with very short fibbers. Paper made

from this type is weaker than that made from softwoods, but its surface

is smoother, and therefore better to write and print on.

Softwood trees:

Softwood trees: It’s

such

as pine and spruce have wood with extended fibers, and paper made from

this type of wood is much stronger. This paper is ideal for creation

produce like shipping containers that require higher strength. But the

finish is rougher, and that’s not as good quality for script, printing

and lots of other uses.

We create newspaper to be opaque (that means that troublesome to

visualize through) – therefore you simply see the newspaper’s comics,

not the securities market report on the opposite side!

We create poke paper sturdy, tissue soft, fine paper sleek. Even inside

an equivalent class there is quite vary. Among printing papers, for

instance, compare the skinny sheets of a Bible to the thick, robust

pages of a kid’s volume.

The basic instruction – wood, water and energy – is adjusted to create simply the paper that is required.

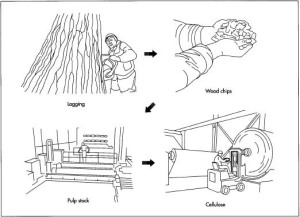

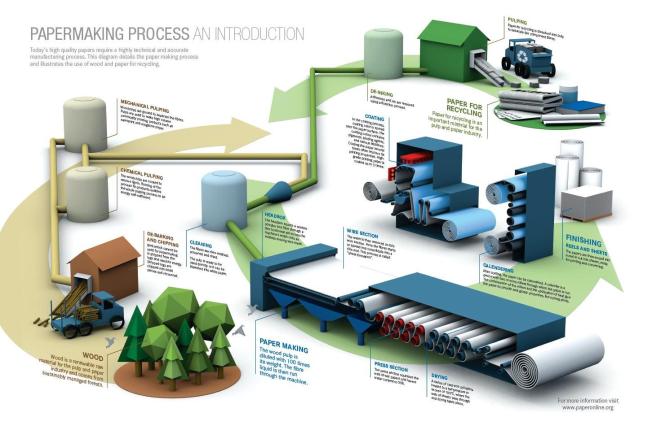

First, workers harvest trees, principally from special tree-growing

areas known as tree farms. When the trees area unit removed, additional

trees area unit planted in their place. Whereas they’re growing, the

young trees turn out several gas, and supply nice home ground for

ruminant, quail, turkeys and alternative life.

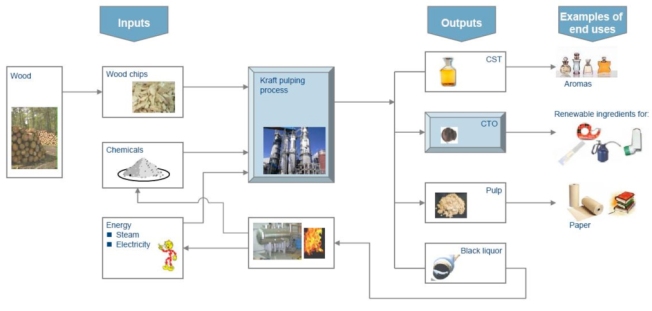

The logs area unit transported to the paper company wherever they get

a shower to rinse away dirt and alternative impurities before being

became little chips of wood. The chips area unit then sorted in line

with size, and moved to the pulping operation, wherever they’re going to

be became pulp for creating paper.

In

the pulping stage, the individual wood fibers within the chips should

be separated from each other. This will be accomplished victimisation

one or additional pulping techniques. the sort of paper that is being

created determines the pulping method that’s used. The finished pulp

sounds like a mushy, watery resolution. However if you scrutinize it

beneath a magnifier, you may see that the individual wood fibers have

all been separated.

Now it is time to form paper out of our pulp. That primarily means

that obtaining the water out of the wood-fiber soup, since this trade

stock is regarding water. The primary space within which this takes

place is named the wet finish of the trade machine.

First, paper-makers spray the stock onto an extended, projection

screen, known as a wire. in real time, water begins to empty out very

cheap of the wire. This water is collected in order that it will be

reused over and another time. Meanwhile, the pulp fibers square measure

caught on the highest facet of the wire, and start to bond along in an

exceedingly} very skinny mat. The fiber mat remaining on the wire is

then squeezed between felt-covered press rollers to soak up additional

of the water.

Even once this wet finish work is over, the non woody stuff on the

wire continues to be regarding hour water. However currently it is time

for the dry finish.

In the dry finish, vast metal cylinders are heated by filling them

with steam. The wet paper, which may be up to thirty feet wide, passes

through these hot rollers – generally dozens of them, and sometimes in 3

to 5 teams. Heating and drying the wet sheet seals the fibers nearer

and nearer along, turning them step by step from pulp into paper.

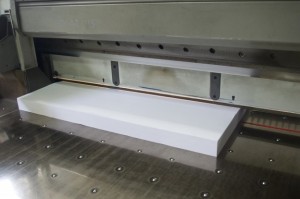

When you investigate a chunk of paper, are you able to notice any

distinction in thickness in this single sheet? Most likely not, due to a

neighborhood of the paper machine referred to as the calendar –

massive, serious forged iron rollers that press the drying paper sleek

and uniform in thickness. Sometimes the paper is coated, usually with

fine clay, to create it glossier and easier to print on. A bit

additional drying then rolled onto an enormous spool or reel, the pulp –

a miraculous mat of fibers from trees – has become paper, prepared for

cardinal uses.

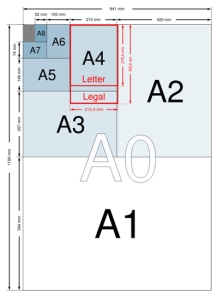

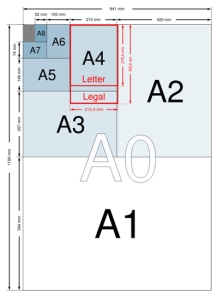

A4

paper and a-like sizes are based on metric dimensions. An A0 piece of

paper, when spread flat, has apart of one square meter and is the

largest dimension at 84.1 cm by 118.9 cm. A0 paper, cut in half, becomes

size A1 at concerning 59.4 cm by 84.1 cm. A1 cut in half is A2, and so

on throughout A6.

A4

paper and a-like sizes are based on metric dimensions. An A0 piece of

paper, when spread flat, has apart of one square meter and is the

largest dimension at 84.1 cm by 118.9 cm. A0 paper, cut in half, becomes

size A1 at concerning 59.4 cm by 84.1 cm. A1 cut in half is A2, and so

on throughout A6. This

produces paper with dissimilar sizes, but all with a 1:1.414

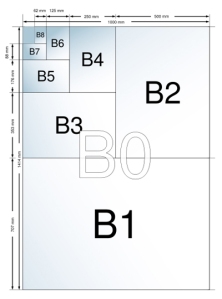

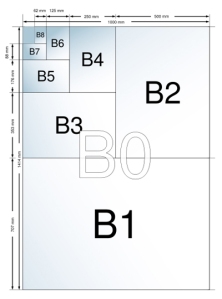

height-to-width part. European standards also wrap B paper sizes. B0

paper is a meter wide and 1.414 meters tall; B1 is B0 cut in semi, and

so forth through B5.

This

produces paper with dissimilar sizes, but all with a 1:1.414

height-to-width part. European standards also wrap B paper sizes. B0

paper is a meter wide and 1.414 meters tall; B1 is B0 cut in semi, and

so forth through B5.

A4

paper and a-like sizes are based on metric dimensions. An A0 piece of

paper, when spread flat, has apart of one square meter and is the

largest dimension at 84.1 cm by 118.9 cm. A0 paper, cut in half, becomes

size A1 at concerning 59.4 cm by 84.1 cm. A1 cut in half is A2, and so

on throughout A6.

A4

paper and a-like sizes are based on metric dimensions. An A0 piece of

paper, when spread flat, has apart of one square meter and is the

largest dimension at 84.1 cm by 118.9 cm. A0 paper, cut in half, becomes

size A1 at concerning 59.4 cm by 84.1 cm. A1 cut in half is A2, and so

on throughout A6. This

produces paper with dissimilar sizes, but all with a 1:1.414

height-to-width part. European standards also wrap B paper sizes. B0

paper is a meter wide and 1.414 meters tall; B1 is B0 cut in semi, and

so forth through B5.

This

produces paper with dissimilar sizes, but all with a 1:1.414

height-to-width part. European standards also wrap B paper sizes. B0

paper is a meter wide and 1.414 meters tall; B1 is B0 cut in semi, and

so forth through B5.